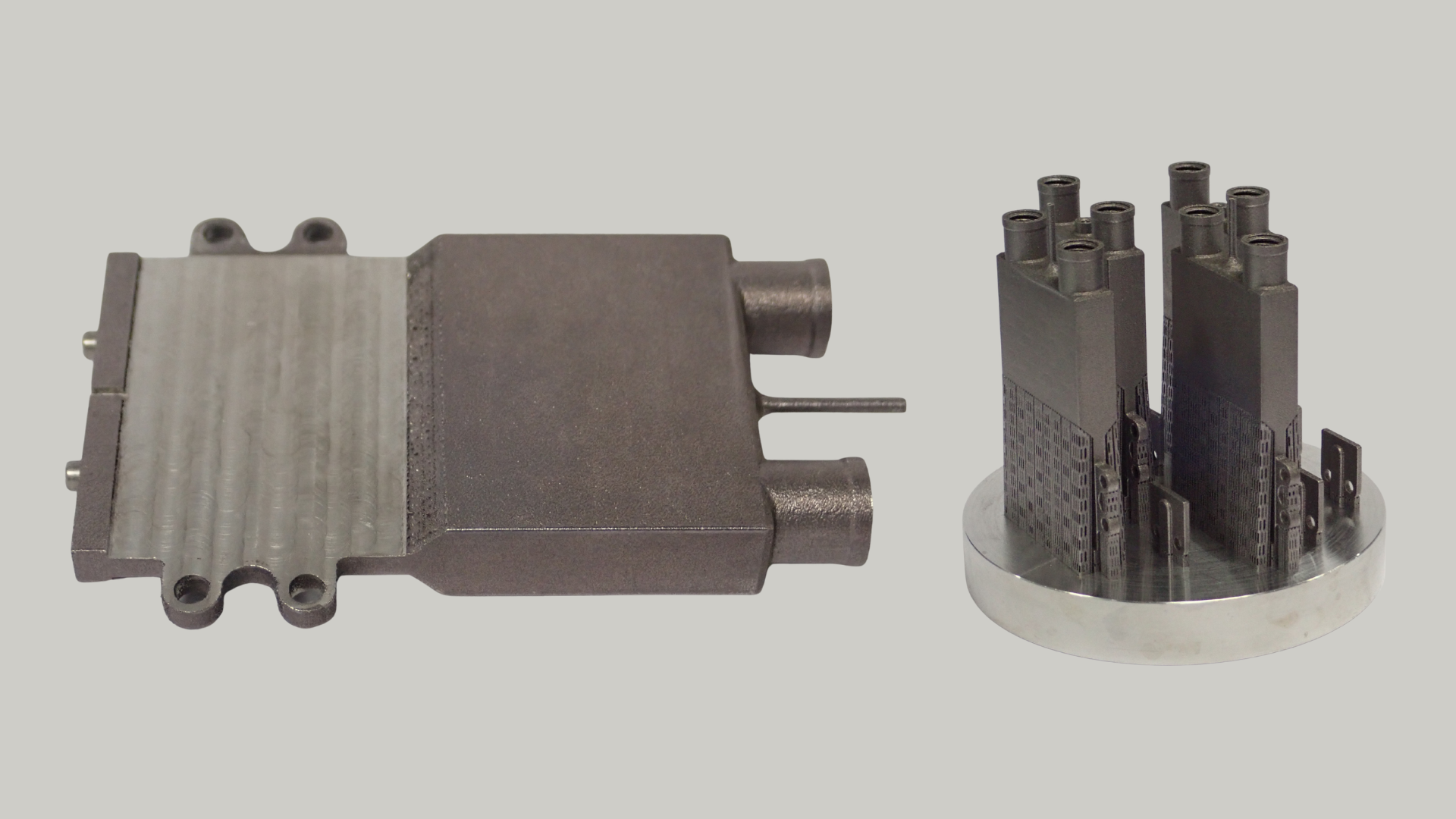

Cold plate prototypes manufactured by CSEM during a previous project in collaboration with JJ Cooling

Additive manufacturing, also known as 3D printing, is playing an increasingly important role in manufacturing, including for scientific instruments. That is why the AIDAInnova project is looking into how the technology can be used to make ultra-thin cold plates for advanced tracking and vertex detectors.

The work is being carried out as part of Work Package 10 of the project, with teams looking into cold plates made from both ceramics and metal alloys.

The work on the alloy versions has been done in partnership with CERN and Swiss technology innovation centre the Centre suisse d'électronique et de microtechnique (CSEM), with the goal to push the boundaries of what is geometrically and functionally possible in cooling systems through AM

The CSEM team chose two alloys for this purpose, Aluminium: Al-12-Si and KOVAR: Fe-29-Ni-17-Co and evaluated various properties, including thermal conductivity, pipe roughness, and the minimum wall thickness required to maintain leak-tightness.

They were successfully able to characterise both alloys and were able to conclude that 3D printing offers several advantages over standard manufacturing processes.

In this interview, CSEM’s business development manager Daniele Brunazzo and R&D engineer Samuel Unterhofer explain the work, why they think 3D printing is so useful for the production of components like the cold plates, and how 3D printing could benefit many more industries outside of high-energy physics.

What are the advantages of 3D-print ultra-thin cold plates rather than manufacturing them in the more common way?

Utilising additive manufacturing for ultra-thin cold plates offers significant advantages over conventional methods due to unprecedented design freedom. This enables the creation of highly intricate internal geometries, such as optimised microchannel and lattice structures, leading to superior heat transfer efficiency and thermal performance. Consequently, these cold plates achieve enhanced cooling capabilities with reduced weight and volume, streamlining integration into compact systems. The process also facilitates rapid prototyping and the consolidation of multiple components into a single, robust part, improving overall manufacturing efficiency and reliability while reducing costs.

You looked at two alloys – Aluminium: Al-12-Si and KOVAR: Fe-29-Ni-17-Co. Why did you choose these two?

Al-12-Si was selected primarily for its excellent thermal conductivity to weight ratio. Its high capacity to efficiently conduct and dissipate heat is crucial for applications demanding effective thermal management, ensuring rapid heat transfer away from sensitive components.

Conversely, KOVAR was chosen due to its precisely tailored coefficient of thermal expansion (CTE). This property is paramount for achieving a close thermal expansion match with other materials within the experimental setup, thereby minimising thermally induced stresses and ensuring structural integrity across varying temperature ranges.

You did a series of tests to inspect the samples – thermal conductivity, roughness, flatness, etc. What were the results?

The material properties of AM Al-12-Si alloy, such as thermal conductivity, are comparable to those achieved through conventional manufacturing methods, indicating low levels of porosity. Tensile properties are typically higher, attributed to the rapid cooling rates characteristic of AM processes.

Laser Powder Bed Fusion (LPBF) tends to produce parts with relatively high as-built surface roughness, primarily due to residual particles that did not melt during the AM process. While this is often considered a drawback in many applications, it can be beneficial for thermal transfer, as the increased surface area enhances heat exchange. However, the higher roughness can negatively impact fluid dynamics, requiring additional energy to maintain fluid flow at the same speed. Measured roughness values are aligned with expectations, ranging from 6 to 20 µm Ra.

Flatness was not evaluated in this study, as the focus shifted towards the development of the smart pipe device. Additional findings related to the smart pipe itself include a minimum achievable hole diameter of 0.44 mm for simple structures and a minimal wall thickness of 150 µm for the 1/8-inch pipe that is leak tight up to 80 bar.

What, if any, are the current limitations of 3D-printing these plates?

Design constraints are primarily associated with extreme geometries, particularly the presence of high overhang angles between large intersecting surfaces. Additionally, it could be possible to have residual powder, especially within exceptionally dense and ultra-thin plate structures. Furthermore, financially speaking, additive manufacturing may not be optimal for geometrically simple designs or conventional applications, where its benefits in complexity are not fully leveraged.

After having done the research, do you think AM could be a good solution for manufacturing ultra-thin cold plates?

Absolutely. Additive manufacturing has high potential for multi-material, ultra-thin cold plates due to its design flexibility, enabling complex internal geometries for enhanced heat transfer. This also facilitates significant reductions in weight and volume through topology optimisation, allowing for the precise integration of diverse materials to achieve tailored thermophysical properties within compact structures.

In what other applications could 3D-printed cold plates be useful (outside of high-energy physics)?

AM has emerged as a transformative technology, offering unparalleled capabilities for diverse industrial applications by enabling the direct fabrication of highly complex and customised components from digital designs. Foremost, AM is extensively used for rapid prototyping and functional tooling, significantly accelerating product development cycles across all sectors. This allows for iterative design refinement and the production of complex jigs, fixtures, and moulds with unprecedented speed and cost-effectiveness.

Secondly, its inherent ability to create topologically optimised and lightweight structures has revolutionised industries such as aerospace and automotive. By precisely placing material only where structurally necessary, AM facilitates the manufacturing of components that boast superior strength-to-weight ratios, leading to enhanced performance and improved fuel efficiency. Furthermore, AM plays a critical role in healthcare, enabling the production of patient-specific medical implants, prosthetics, and surgical guides with intricate geometries tailored to individual anatomical requirements, thereby enhancing patient outcomes and recovery.

The technology also supports on-demand manufacturing of spare parts and low-volume production runs, mitigating reliance on extensive inventories and streamlining global supply chains. This capability is particularly beneficial for obsolescence management and reducing lead times. Finally, AM facilitates the creation of functional components with integrated functionalities, such as complex internal cooling channels or embedded sensors, pushing the boundaries of component performance and system integration in demanding environments. This comprehensive utility underscores AM's profound impact on modern industrial production.

The core CSEM team working on the AIDAInnova project involved Samuel Unterhofer, Václav Pejchal, and Silvia Biselli.